Home News Industry-news Precision Injection Molding And Molding …

Precision injection molding and molding technology is a key process used to manufacture housings, enclosures or support structures. These housings and structures are often used to protect electronic components, connectors, cables and other parts to ensure the reliability and safety of the PCBA. Here is some important information about precision injection molding and molding technology:

1. Material selection

Selecting the right material is critical to the injection molding and molding process. Commonly used materials include plastics (e.g., polypropylene, polycarbonate, polyimide, etc.), rubber, silicone, and so on. Material selection should be based on application requirements such as heat resistance, corrosion resistance, mechanical strength and electrical insulation.

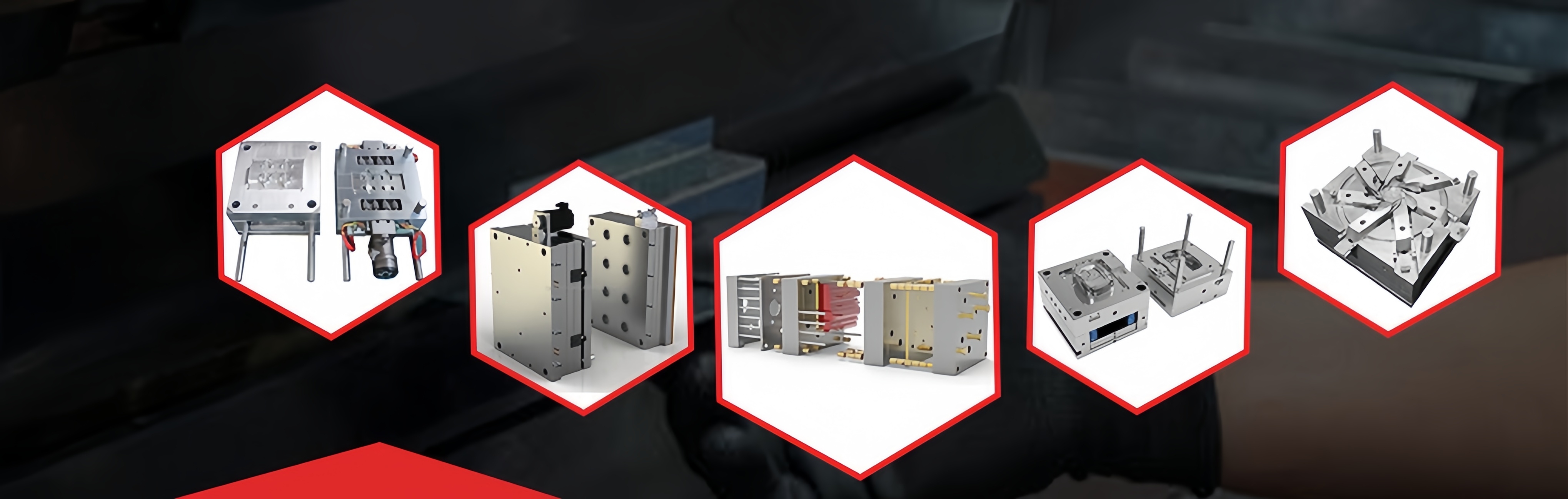

2. Mold design

The design of molds for manufacturing precision injection and molded parts must be accurate and take into account the geometry, dimensions and special requirements of the parts to be produced. Molds usually include injection molds and press molds.

3. Injection molding process

Injection molding is the process of injecting heated plastic material into a mold to form the desired part or housing. Precision injection molding process requires strict control of temperature, pressure and injection time to ensure the quality and accuracy of the part.

4. Molding process

Molding is typically used to create housings, support structures, or other specially shaped parts. Molding can be hot molding, cold molding, compression molding and other different processes, depending on the material and requirements.

5. Surface treatment

After completing injection molding and forming, surface treatments such as polishing, painting, silk-screening or coating may be required to meet aesthetic and protective requirements.

6. Quality Control

The precision injection molding and forming process requires strict quality control, including checking the size, appearance, integrity and material properties of the parts to ensure they meet specifications and requirements.

7. Automation

For mass production, automation techniques can improve productivity and consistency. Automation includes automated mold loading and unloading, automated injection and molding machines, and automated quality inspection systems.

8. Environment and Sustainability

Considering environmental sustainability is an important factor in modern manufacturing. Choosing recyclable or biodegradable materials, optimizing processes to reduce waste, and reducing energy consumption are all sustainability considerations.

In summary, precision injection molding and molding technologies play an important role in PCBA manufacturing by providing enclosures, support structures, and protection for electronic products while ensuring part quality, reliability, and performance. Selection of appropriate materials, mold design and process control are key to achieving a successful injection and molding process.

Name: Mrs. wang

Mobile:+8613922546862

Whatsapp:+8613922546862

Email:lxwei@weiyumold.com

Add:Yang Wu Industial Zone, Dalinshan Town, Dongguan City, Guangdong Province, China